We provide expert system integration service to our customers, with particular emphasis on Programmable Controllers, HMIs, and Motion Products. We are committed to maintaining trained personnel and the latest testing equipment to provide technology specific services to our customers.

ALL PRO Controls & Manufacturing Division understands all aspects of control system design, engineering, implementation, and support. We have been implementing Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), Human Machine Interfaces (HMI), along with a multitude of other control systems since 2001. During each of our projects, we strive to implement creative, high quality, cost-effective solutions in order to meet and exceed our customer’s current and future business needs.

We provide solutions for all of the following customer control systems:

Getting the most out of your equipment requires a control system which has key business drivers in mind: quality, flexibility, and operation efficiency. We achieve these goals by studying the customer’s operational requirements and applying the optimal machine control and information solution. Our customers have improved production and lowered risk once the project is completed. They have also benefited from improved operator training and interfaces, lowered maintenance cost, better diagnostic information, and detailed data analysis.

We also integrate solutions on a variety of motion control automation platforms in high performance, demanding applications. If obsolete motion control systems are causing problems, we can retrofit them with new controls. We can take obsolete OEM motion control systems and define the migration path to upgrade machines to the latest motion control technologies.We can provide solutions for all of the following motion control systems:

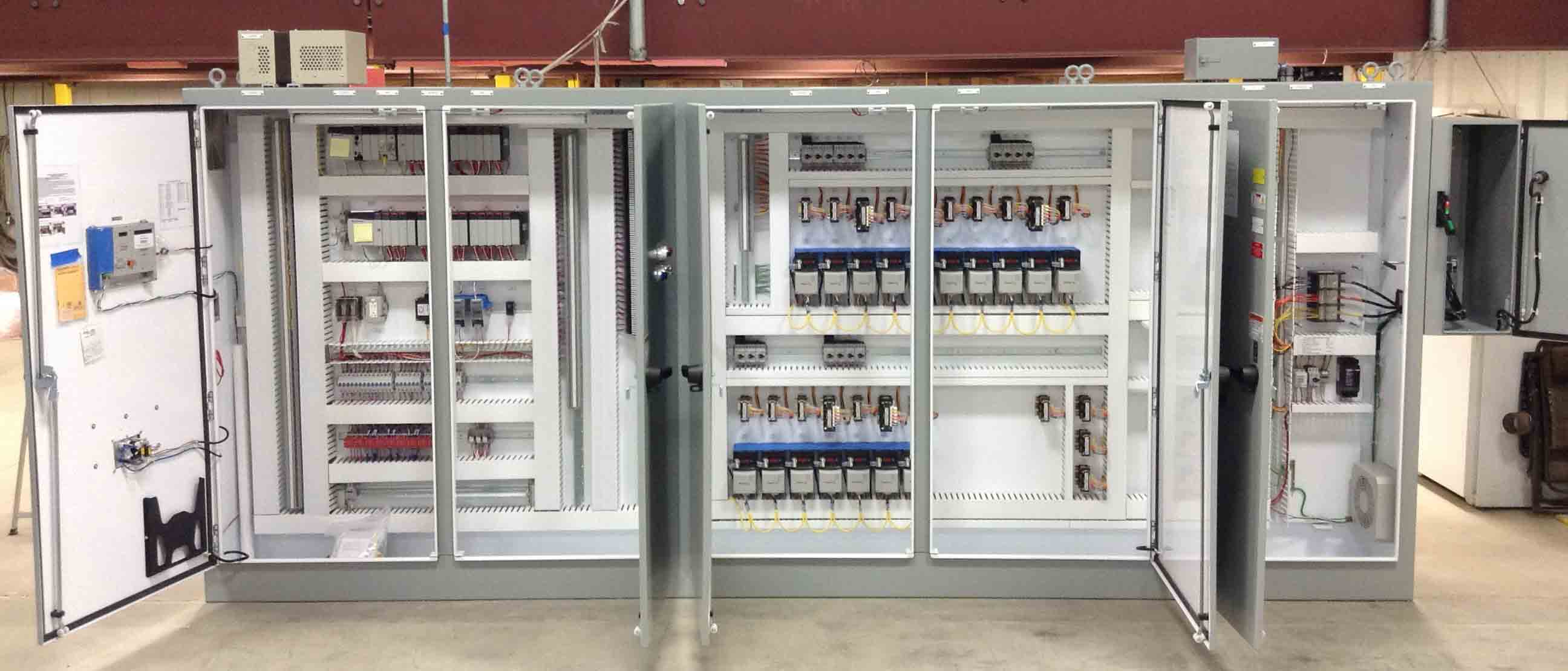

ALL PRO Controls & Manufacturing Division has a team of experienced technicians with both electrical and mechanical expertise in custom panel building and machine assembly and wiring. Our technicians implement high-tech components into many automation processes and use checklists to ensure the highest level of quality assurance. We take care to ensure all equipment is installed professionally and safely, and can be easily maintained in your facility.

We operate an Underwriters Laboratory (UL) Certified Panel Shop. Our expert panel builders are known for their quick turnaround time, for their UL listed capabilities, and for turning out high-quality products. We build turnkey electrical and mechanical products through our internal engineered designs or from customer engineered designs. Through our mechanical division, we can shear, bend, brake, or machine most metal alloy components needed for a custom control solution. We take great pride in performing thorough point-to-point wiring checks for every panel we build. We also perform power-on checks for every panel we build. We maintain a strict quality control procedure on every item manufactured, assembled, and wired.ALL PRO Controls & Manufacturing Division provides industrial control panel solutions for packaging, process facilities, utilities, and other industrial applications. We earn repeat business by offering quality, value, and service above and beyond our competitors. Our designers are degreed engineers, professionals, and high skilled electrical technicians who bring extensive experience to the design and implementation of control panel solutions for a wide range of industrial applications.

Our design team ensures all panels are designed to meet the specific needs of each customer. Panels are designed with specific operational goals in mind, with intense focus on safety, accuracy, value, and reliability. Upon request, our design team provides factory acceptance test (FAT) services base on customized FAT documents developed specifically for each application.ALL PRO Controls & Manufacturing offers over 30 years of combined experience building high quality control panels and electrical control systems. We also maintain long standing relationships with leading technology suppliers. We build custom panels to each of our customer’s specifications – whether they use their own designs or ours – and provide inventory control and shipping to designated sites across the country.

Project Management:

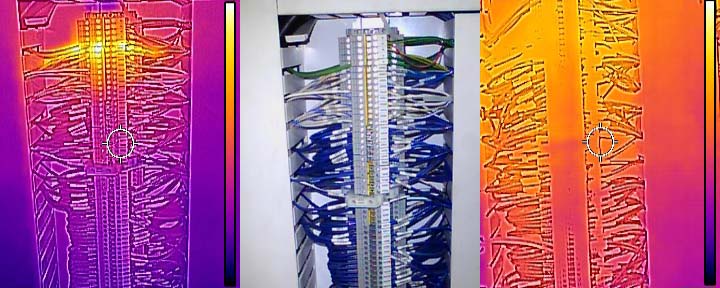

Certifications & Inspections

Process/Machine Analysis

Our professionals have extensive experience in process development, production technical support, validation, and information transfer. Using multivariate analytical (MVA) techniques and tools, we identify critical process variables to successfully troubleshoot each project. These capabilities enable us to analyze the process that identifies sources of variation, assess the size and impact of the variation, and implement programs to control the variation.Field Support Services

ALL PRO Controls & Manufacturing Division will accurately analyze your equipment if it is operating erratically, not performing properly, or has broken down unexpectedly. Our field technicians can travel to your facility to assist your teams with repairs. If your requirements are parts-related, we will work with our vendors to repair or replace them quickly to minimize downtime.Other types of support services available are:

Quality Design Packages

ALL PRO Controls & Manufacturing Division has a team of systems integration engineers and technicians who have experience with all major brands and platforms of PLCs-based control systems. While the majority of the control systems are based on Rockwell Automation’s controllers, we have extensive experience working with other systems. These systems include Siemens, Fanuc, Cognex, Keyence, AutomationDirect, Mitsubishi Electric, and Eaton, as well as other hardware and software partners. We take care to ensure our vendor relationships are aimed at providing our customers with the best solutions for their applications. We generate quality design packages for controls and systems integration including control panel layouts, bills of material, electrical schematics, detailed functional control specification, PLC programming, and custom software. Panel construction and machine wiring is performed under the supervision of licensed electricians. Our engineers provide extensive customer support during testing and debugging of systems and on-site support for start-up and training.Professional CAD Services

Our design team includes degreed engineering professionals to ensure all electrical designs and panels meet the specific needs of each customer. Our automation systems are designed with specific operational goals in mind, and with intense focus on safety, accuracy, value, and reliability. We also provide factory acceptance test services developed specifically for each application.Design capabilities include:

Upgrade Services

Manufacturing customers should expect their control system equipment to perform year after year when given proper care. However, older system components, especially windows-based equipment, can become problematic and lead to increased maintenance costs and downtime. In addition, spare parts are harder to find as time goes by and hardware is discontinued.When these situations occur, it is time to upgrade your legacy system. ALL PRO Controls & Manufacturing Division has the expertise to ensure a seamless migration. Our engineers have the knowledge and legacy systems experience required to develop the right migration strategy for your needs. Our proven migration methodology prioritizes component upgrades based on the level of necessity, the desire to limit total project costs, and the need to minimize disruptions to production.